Europe

Quarrying, Mining and Construction

NSK Bearings for the Quarrying, Mining and Construction Industries

Don't let unplanned downtime reduce your productivity.

Don't let unplanned downtime reduce your productivity.Durability and reliability are of paramount importance for mining machinery operating in remote locations such as mountains or deserts, where failure of a single component can impact the entire mining operation. NSK bearings offer both equipment manufacturers & Quarry and Mine operators longer service life under the most arduous and challenging operating conditions. Our aim is to help you maximise uptime and reduce maintenance for improved productivity at your mining sites.

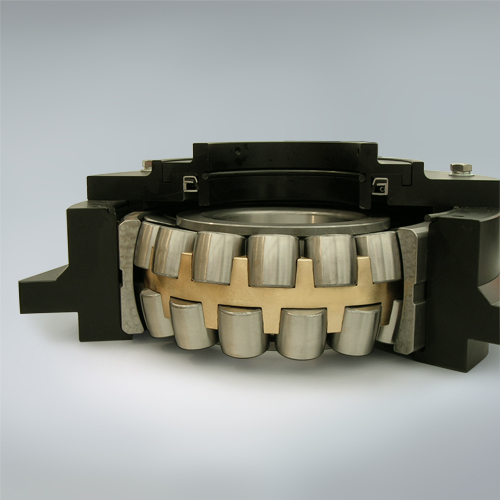

NSK has applied state-of-the-art technology to material, lubrication, sealing and design to ensure that the bearings exceed the life and limiting speed of conventional bearings. Our superior bearings offer high performance with robust design, improved wear & seizure resistance in contaminated environments to give you a longer operating life and enable you to reduce energy, downtime and maintenance costs.

Lubrication

Vibration & Shock loads

Increase your profitability & reliability - AIP

Extraction

Digging, Drilling and Blasting the Ore

NSK Bearings are used in some of the toughest terrain and inaccessible locations of a mining site. Whether it's digging an access tunnel, removing the ore, or attaining mineral deposits drilling machinery, bearings used in draglines and shovels need to be reliable. NSK technology, service and experience can help you maintain your production momentum.

Crushers for quarrying & mining

Achieving longer life from Quarrying conveyors

Transport

Stack, Doze or Carry - NSK Bearings Help You Lighten the Load of Maintenance

Heavy loads, shock loads, vibration, misalignment and debris all contribute to machinery wear, but NSK bearings can help lighten the load of maintenance with specifically designed vibration and wear resistant bearings helping you to extend your plant production life.

NSK has worked with equipment manufacturers, contractors and mine operators worldwide to create bearings which meet their working needs, and we will continue to develop and invest in new technology to ensure your machinery continues to perform.

Transportation around the mining and quarrying sites - conveyors, dumper trucks, loaders, reclaimers, mobile plant and much more...

Preparation

Crush, grind, screen, blast...It's a tough life to prepare, separate & enrich minerals

The very harsh environments of the mineral preparation, separation and enrichment processes demand that machinery is pushed to the limits with weight and vibration, and contamination is a constant problem.

By understanding and working with equipment manufacturers and mine operators (for static and mobile plant) over the years NSK has been able to develop and design bearings which continue to perform through permanent states of misalignment, shock loads and vibration, to ensure that your machinery keeps performing even under such extreme conditions.

We can advise and help you with fitting, lubrication, sealing and bearing selection to suit your needs.

NSKHPS Angular Contact Ball Bearings for improved pump life

Longer Life Pumps

Construction

Construction Industry

Drivetrains, transmissions, gearboxes or wheel bearings in major construction machinery require reliability under high stress conditions. NSK bearings deliver these requirements and can help you reduce energy & power consumption. Our designs and material options help increase your machines resistance to heavy loads, shock & vibration, whilst ensuring contamination does not impede performance.

Total Quality Solutions:

Anti-creep dump truck bearings

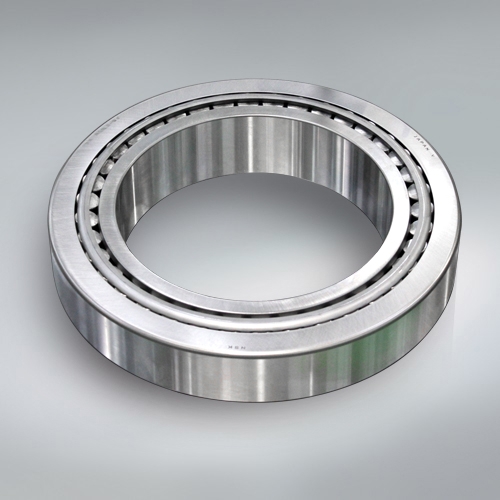

Taper Roller Bearings

Triple Lip seal inserts

EM / EW Cylindrical roller bearings

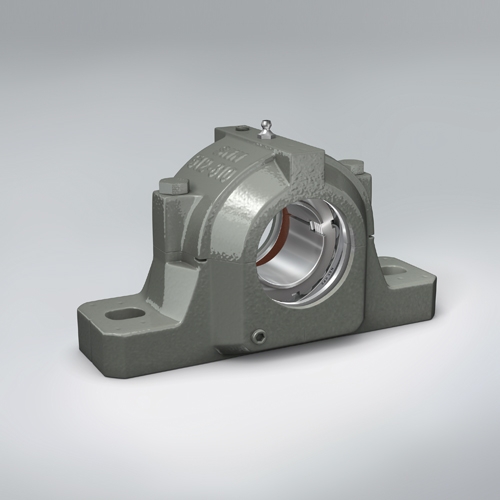

Self-Lube® units

Crane sheave bearings

Cage & roller assemblies

Integrated bearings assemblies

English

English العربية

العربية беларуская

беларуская Bosna i Hercegovina

Bosna i Hercegovina Български

Български Česky

Česky Dansk

Dansk Deutsch

Deutsch Español

Español ελληνικά

ελληνικά Français

Français עברית

עברית Hrvatski

Hrvatski Italiano

Italiano Lithuania

Lithuania Magyar

Magyar Македонски

Македонски Nederlands

Nederlands Norsk

Norsk Polski

Polski Română

Română Русский

Русский Slovenčina

Slovenčina Slovenščina

Slovenščina Cрпски

Cрпски Suomi

Suomi Svenska

Svenska Türkçe

Türkçe Український

Український 日本

日本 US

US Canada

Canada

Mexico

Mexico Brazil

Brazil Latin Americas

Latin Americas